To date, cncKad has supplied more than 1,300 different machine models from more than 160 manufacturers with electric power. Geometry, dimensions, and technology (punching/cutting) are fully associative If you change the geometry, cncKad will automatically update the dimensions and definitions for punching or cutting. Import all standard 2D and 3D project formats Use of various technologies to process sheet metal products Generate NC codes for almost any machine on the market.ĬncKad 18 is the only system that integrates CAD / CAM functions in the same module. Metalix software supports the production life cycle: Equipped with over 150 new functions and support for the latest machine models and sheet metal machining technology, the V18 is sure to increase your productivity, machine usage, and materials. Read about the flow of data when using the Metalix API.įor instructional videos on this topic products, go to Metalix YouTube Channel.Metalix CNCKAD V18 Test with Dongle / Clone or CrackĪnnouncing the official release of the cncKad V18 After extensive field testing, the cncKad V18 was officially released. Many applications already utilize the facilities that Metalix provides for integrating with its powerful software. This solution allows you to fully automate the production process from ERP to NC code, and feed the output back to the ERP. You can use the API to integrate cncKad and AutoNest with ERP/MRP systems.

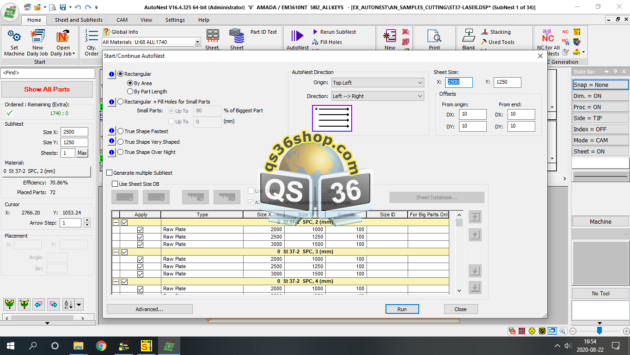

Using the API and the parametric programming module, you create programs that control all aspects of cncKad and AutoNest operations, from part loading to punching/cutting, automatic nesting, and NC code generation. Those modules come with complete documentation and a set of code examples in VB.NET and C#. cncKad can load PPD definition files created by ERP/PDM systems. Parametric Programming / API / ERP IntegrationĬncKadand AutoNestoffer an extensive Application Program Interface (API), so they can be tailored to any specific application, and connected to any ERP/MRP system.ĬncKad includes a complete development environment for creating, running, and debugging Parametric Part Description (PPD) files.

0 kommentar(er)

0 kommentar(er)